Demag UZ Air Motors – Sole Agent for Southern Africa

ECS is the exclusive agent for the import and supply of Demag UZ Air Motors in South Africa and Southern Africa.

The Demag UZ Air Motor range is manufactured in Germany and is renowned for its reliability, safety, and durability. As these motors require regular maintenance to ensure safe operation and maximum service life, ECS has invested in highly skilled technicians and workshop personnel with experience in the servicing and repair of Demag UZ Air Motors.

All repair and service work is carefully inspected and fully documented by our technicians and management team. Clients are kept informed throughout the process, ensuring complete transparency and confidence that every unit is returned to site in optimal working condition.

Demag Helical-Gear Air Motors – Designed for Safety and Reliability

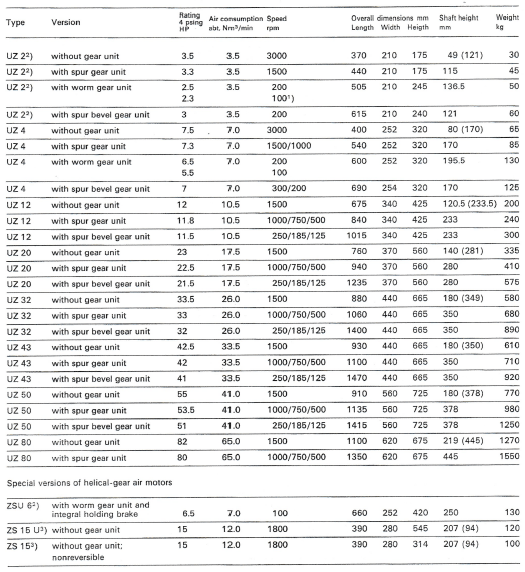

Demag UZ helical-gear air motors are used as prime movers for a wide variety of machinery, particularly in applications where compressed air offers clear safety and operational advantages. Their robust, uncomplicated design and exceptional reliability have made them a preferred choice in:

-

Underground mining

-

Chemical and petrochemical industries

-

Metallurgical plants

-

Marine and offshore applications

Years of operational experience and close collaboration with end users have resulted in a comprehensive range of accessories to suit diverse industrial requirements.